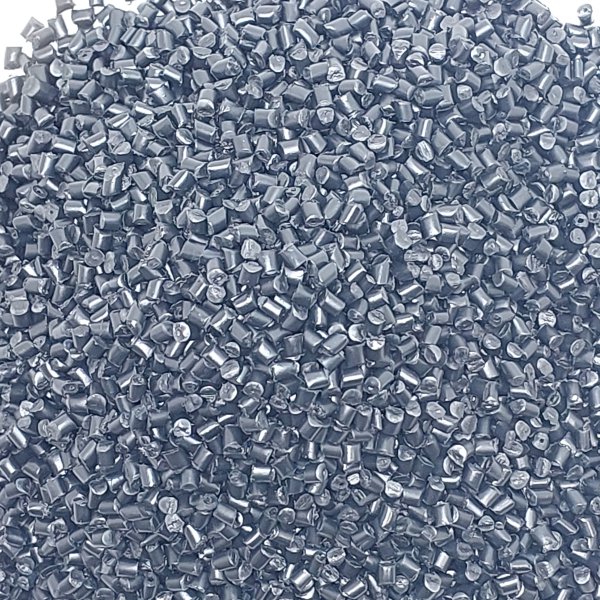

PP 8900-OP Polypropylene Compound: Tailored Excellence in Performance, Color, and Versatility

PP 8900-OP is a customized product tailored to meet customer needs in terms of all properties and colors. It has a good gloss level and high colorability. Its low density, high tensile and flexural strength, stability, good thermal resistance up to about 100 degrees, and good electrical properties make it an excellent insulator for high-frequency applications. It does not absorb moisture even at low temperatures and is resistant to wear and corrosion. Its moldability is good.

Unlocking the Advantages of PP 8900-OP Polypropylene Compound: Ideal for Precision Screw-Based Parts

Due to its unique mechanical and thermal properties such as high moldability and resistance to fracture even at low temperatures, PP 8900-OP is the best choice for producing screw-based parts (Parts that need to be assembled with screws) such as plastic body vacuum cleaner frame screws. It is an engineered polymer that combines desirable copolymer properties with moldability, resulting in economic benefits.

In Which Application Areas is PP 89000-OP Polypropylene Compound Used?

PP 8900-OP Polypropylene Compound is used for Any industry that requires polypropylene copolymer in the injection molding process, such as household appliances like vacuum cleaner parts, washing machine parts, etc.

فارسی

فارسی العربية

العربية

Reviews

There are no reviews yet.