Polystyrene is a kind of polymer that is translucent, stiff, brittle and quite robust when left unaltered. It is a polymer-made plastic composed of styrene, one of its constituent building blocks. It is used in different forms, including foam, film and rigid plastic, for applications from food packaging to electronics protection. While polystyrene’s uses are flexible and have a low shrink rate, it also flows slowly and can come out brittle. Polystyrene is food safe, though it can leach styrene over time. Here, we’ll talk more about this amazing material.

Table of Contents

What is Polystyrene?

Polystyrene is a type of polymer that belongs to the family of plastics. It is derived from styrene monomers and is known for its rigid and lightweight structure. Let’s talk more about the styrene monomer and how polystyrene is made:

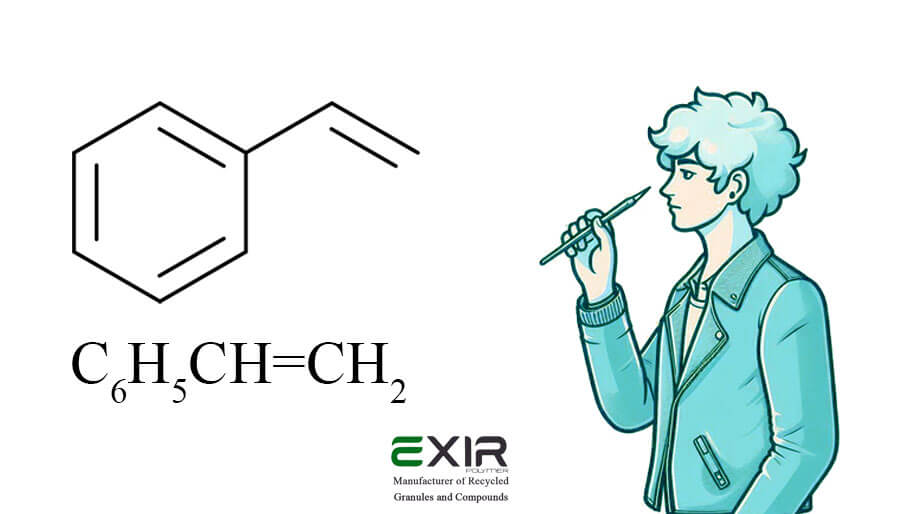

What is Styrene?

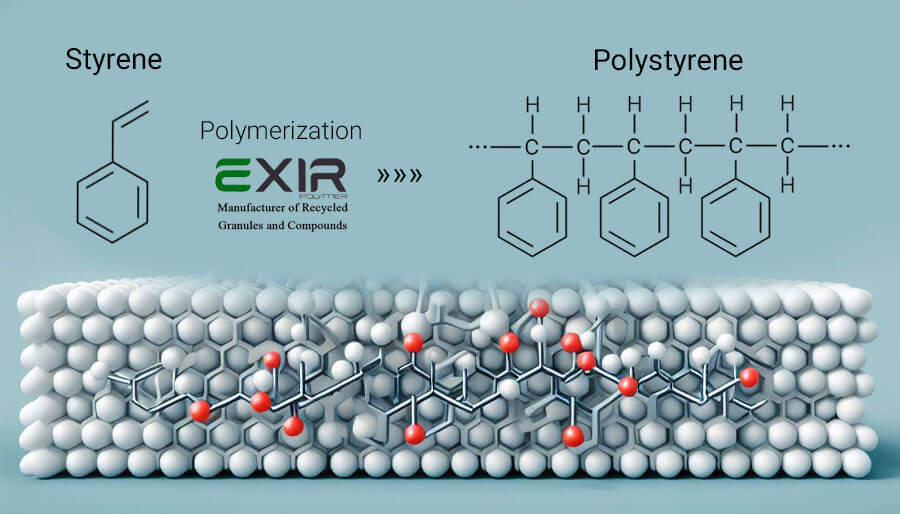

Polystyrene, a widely used polymer, is derived from the monomer styrene. Styrene is a transparent liquid predominantly derived from petroleum. It is classified as an aromatic compound and belongs to the family of vinyl monomers. Through a polymerization process, styrene molecules undergo a chemical reaction that results in the formation of the polymer known as polystyrene.

Styrene itself finds extensive industrial applications beyond polystyrene production. It is utilized in the manufacture of various plastics, resins, and synthetic rubber. One notable example is the production of acrylonitrile-butadiene-styrene (ABS), a versatile thermoplastic known for its strength, rigidity, and impact resistance. ABS is widely used in industries such as automotive, electronics, and consumer goods due to its excellent mechanical properties.

Overall, styrene serves as a crucial building block in the production of not only polystyrene but also a range of other important polymers that contribute to numerous industries and applications. Its versatility and wide range of applications make it a valuable component in the manufacturing sector.

How is Polystyrene Made?

Polystyrene is produced through a polymerization process involving the mixing of styrene monomers. Suspension polymerization and continuous mass polymerization are the two basic techniques for achieving its goals.

An initiator of free radicals and a suspending agent serve to keep styrene monomers suspended in water during the suspension polymerization process. Beads made from this polymer are produced when the mixture is heated and the initiator starts the polymerization process. Foam and solid sheets are only two more shapes that may be created from these beads through further processing.

On the other hand, styrene monomers are heated and mixed in a reactor during continuous mass polymerization. Long chains of polystyrene are formed by the polymerization of the monomers, which is triggered by the addition of a free radical initiator. The molten polystyrene may then be molded using molding processes to take on the appropriate shapes.

Polystyrene Uses

Because of its advantageous qualities, polystyrene is widely utilized in various applications and industries. Let’s check out some of the main applications for this polymer that are frequently used:

Polystyrene in Construction

Design flexibility and structural integrity are provided by expanded polystyrene (EPS). EPS sheets are a popular choice for construction panels because of their superior thermal insulation qualities. In structures, Structural Insulated Panels (SIP) are used for floors, ceilings, external walls, and roofing. It is quite beautiful and may be used as decoration as well.

Because Insulating Concrete Forms (ICF) are more attractive, safer, and have a longer lifespan, they are quickly gaining popularity in the building industry. A quiet and serene indoor environment is produced by the EPS foams’ acoustic insulation feature. To support the weight, EPS foams come in a range of compressive strengths.

Polystyrene in Automotive

Polystyrene, a lightweight material with energy absorption properties, durability, and moldability, is a valuable material in the automotive industry. Expanded polystyrene (EPS) foams are widely used in automobile components, such as seat cushions, dashboards, door panels, and bumpers. EPS foam’s high-impact absorption capability ensures passenger safety by absorbing and dispersing energy during collisions. Its lightweight structure improves fuel efficiency by reducing vehicle weight, leading to better mileage and reduced emissions.

Its moldability allows designers to create elegant and comfortable interiors, resulting in aesthetically pleasing designs. Its cost-effectiveness makes it an attractive choice for automotive manufacturers. It is also used as a shock-absorbing liner in helmets, protecting the head from potential injuries during accidents or collisions.

Polystyrene in Packaging

Packaging applications are among the most widespread uses of this polymer. Food products, electronics, and fragile goods are all packaged to protect them using polystyrene foam, sometimes referred to as Styrofoam. Because of its cushioning qualities and its weight, the foam helps shield the contents from harm while being transported.

Foodservice disposables such as plates, cups, and containers are also made of polystyrene. Either hot or cold food or beverages may be kept at the right temperature because of their insulating qualities.

Polystyrene in Appliances

Polystyrene’s electrical resistance and insulating properties make it an ideal choice for the manufacturing of appliances. It is commonly used as an insulating material to maintain low temperatures and enhance energy efficiency, specifically in freezers and refrigerators. By incorporating polystyrene foam, heat transmission is minimized, effectively keeping the interior cool.

This insulation helps to prevent the entry of external heat, allowing the appliances to maintain the desired temperature and reduce the workload on the cooling system. As a result, this polymer contributes to the overall energy efficiency and performance of appliances in the refrigeration industry.

Polystyrene in the Medical Industry

Polystyrene is used in medical packaging, diagnostic tools, and laboratory apparatus. In research and diagnostic labs, polystyrene petri dishes, test tubes, pipettes and cuvettes are frequently utilized. These goods offer the perfect surface for the cultivation of germs and cells since they are clear and sterile.

Blister packs for medications are one type of medical packaging that uses polystyrene. The material ensures the integrity and safety of the contained medical supplies by providing protection from light, moisture, and contamination.

Polystyrene in Food Service

Because of its cost, durability, and insulating qualities, it is used extensively in the foodservice business. Foam cups, plates, trays and takeaway containers are frequently made using it. For serving hot coffee or iced drinks, polystyrene foam works wonders by maintaining the temperature of hot liquids at a high level.

Its foam is also used by foodservice businesses as a takeout and fast food packaging material. Its insulating qualities and small weight make it easier to keep the meal hot and fresh throughout delivery.

Polystyrene Properties

Polystyrene possesses several key properties that contribute to its widespread use in various applications.

Lightweight

Polystyrene’s lightweight nature provides significant benefits in terms of handling and transportation. Its low weight makes it easy to work with and maneuver, reducing the physical strain on workers. Furthermore, the lightweight property of it is particularly advantageous in industries where weight reduction is a priority, such as the automotive and packaging sectors.

In automotive applications, the use of lightweight polystyrene components helps improve fuel efficiency and overall vehicle performance. Similarly, in the packaging industry, lightweight polystyrene materials contribute to cost-effective and efficient shipping, reducing transportation expenses and environmental impact.

Thermal Insulation

Polystyrene’s exceptional thermal insulation properties make it a highly advantageous material in construction, appliances, and packaging. It effectively conserves energy and helps maintain temperature stability, contributing to energy efficiency, improved comfort and the protection of goods during storage and transportation.

Chemical Resistance

Polystyrene’s resistance to chemicals, oils, and greases makes it a reliable choice for applications where exposure to these substances is expected. Additionally, its ability to withstand water and moisture ensures its suitability for use in wet environments or applications that involve contact with liquids.

This chemical and moisture resistance enhances the durability and longevity of polystyrene-based products, making them suitable for a wide range of industries such as food packaging, medical equipment, and marine applications.

Electrical Insulation

Polystyrene’s outstanding electrical insulating properties make it highly suitable for a variety of electrical and electronic applications. Its low electrical conductivity acts as a barrier, impeding the flow of electricity and reducing the risk of electrical hazards. This characteristic allows it to be used in electrical insulation systems, circuit boards, capacitors, and other electronic components where reliable electrical insulation is crucial for safety and performance. The ability of polystyrene to effectively isolate electrical currents contributes to the overall reliability and efficiency of electrical systems and devices.

Transparency

Polystyrene can be produced in a transparent form, offering exceptional visibility and clarity. This characteristic is particularly advantageous in applications where visual inspection is essential, such as medical devices and packaging. The transparency of this polymer enables healthcare professionals to easily monitor and assess medical equipment, while in packaging, it allows for clear visibility of the enclosed products, enhancing presentation and marketing appeal. The ability of transparent polystyrene to provide a clear view without compromising its other desirable properties makes it a versatile choice in industries that prioritize visual inspection and product visibility.

Versatility

Polystyrene is a highly versatile material known for its ease of molding, extrusion, and forming capabilities. It can be shaped into various sizes and configurations, offering flexibility in design and application. Whether produced as solid sheets, foam, or molded products, the adaptability of this polymer allows for diverse uses in industries such as construction, packaging, automotive and consumer goods.

This versatility enables manufacturers and designers to create customized solutions tailored to specific requirements, while also benefiting from polystyrene’s other desirable properties such as lightweight, insulation, and durability. The ability to mold it into different shapes and forms makes it a preferred choice for a wide range of applications.

Conclusion

Polystyrene is a versatile polymer with widespread application in a variety of sectors. Because of its cost-effectiveness, insulating qualities, and lightweight design, it is a well-liked option for use in the food service, automobile, appliance, building and medical industries. The characteristics of this polymer, such as its chemical resistance, transparency, and adaptability, add to its many uses. It is anticipated to be a useful and important material in a variety of applications as long as companies keep innovating and searching for effective and sustainable materials.

فارسی

فارسی العربية

العربية

Khaleesi Enriquez

Terrific article! That is the type of information that are meant to be shared

around the internet. Shame on the seek engines for

now not positioning this publish upper!

Thank you =)

Excellent post. I was checking continuously this

blog and I am impressed! Very helpful information specially

the last part 🙂 I care for such information a lot. I was seeking this

certain info for a long time. Thank you and best of luck.