About Exirpolymer

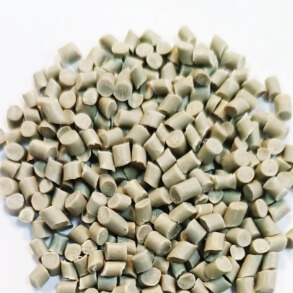

We as the Exir Polymer Company focus on the production and development of recycled plastic compounds in the fields of PP, PS, PC, PE, and ABS. With advanced production equipment and adherence to standardization principles in the production process, the company is committed to improving its activities. In addition, new application programs, skilled and dedicated human resources, and international expansion are also factors contributing to the success of this company. For this reason, Exir Polymer holds a special position in the industry of producing recycled plastic compounds

The Company’s Story

Everyone Has a Story

An Elixir is a substance that changes the nature of objects and makes them more valuable, for example, turns copper into gold. Exir is the Persian word for Elixir, which is used in our company’s name and shows how valuable our work is in the industry.

Episode One

Exir Polymer started its production activity in October 2013 with the slogan of maintaining and improving quality and paying attention to customer needs with a typical granulation line; a 120 single-stage Line.

What was Exir’s work plan? Production of HIPS (High-Impact Polystyrene) + GPPS (crystal) -combined granules for photo frame production factories.

Exir’s office was located in Yazd and production was carried out in this city as well as Ramsheh. Production tonnage is 40 tons per month in a small factory space with two 100-meter halls.

From the beginning, Exir Polymer has been familiar and committed to the value of deep knowledge and understanding (about competitors, self-awareness and most importantly, about customers and their needs). After a year, we found that the HIPS and GPPS (crystals) that the grinders deliver to us as washed cargo have no standard and optimal washing process.

Therefore, the mission defined for Polymer Exir was to solve this challenge. We did not pay attention to the despair of those around us and the negative energy of our competitors and colleagues. When we recognized the problem, we evaluated different solutions and came to the conclusion that we should design and assemble the washing line ourselves and improve the quality of the input material as much as possible and be able to add to the value of the product and keep and satisfy our valuable customers.

With a lot of trial and error, spending a lot of money along with the patience and companionship of the managers, a semi-mechanized washing line was set up with the aim of improving producing HIPS – GPPS combined granules for the end customers who were actually managers of photo frame factories. At the same time, two other normal granule-making lines were also purchased and added to the factory.

At the end of the first chapter of Exir’s life; the peak of our activity was three conventional and normal two-stage granulation lines and a semi-mechanized washing line.

Due to the low technology of the devices, we had not reached our goal of producing quality products; Although at this stage, the quality of our production was excellent compared to other competitors in the market, we were still low compared to our own and global standards.

Most of our focus is on self-improvement and self-protection, according to these principles at this time, the need to develop devices and machines was strongly felt.

During these days, there was no shortage of colleagues, friends and acquaintances who gave us negative energy and kept saying that our strategies were wrong and how and why we spent so much for the production of HIPS-GPPS compound.

But Exir Polymer has always been and is determined that when after consultations, evaluation and analysis of market and industry information, it defines a flexible road map to continue the path with strength and patience despite all the adversities and negative energies. Here we entered the second season of our business to solve the same problem.

Episode Two

What was our decision?

Exir Polymer’s ambitious decision was to purchase a complete standard granulation line with high production capacity and assembly.

Exir’s decision was implemented on ……: we purchased and launched a plastic granulator machine with 160 barrels and Screws, two-staged and 4-meter size, die: 50 Mesh Screen, etc.

The differences gradually became more obvious. We are the first business to use a 50 Mesh Screen device to produce recycled granules; while the vast majority of our colleagues were using 33 ones.

We became the founder of the high-quality production line in the plastic recycling industry and the best in “Recycled HIPS – GPPS Compound “. The difference and distinction is getting bolder and bolder and the optimality of Exir managers’ road map despite the many issues and challenges is clearer.

It was here that the Exir Polymer brand was introduced as a professional Iranian Manufacturer of granules that maintains and improves the quality of its products in the Iranian plastic market, and we reached valuable customers whose efforts to meet their needs have been fruitful. It has been and will be our best motivation and incentive in this industry.

Exir Polymer these days, despite the fact that not much time has passed, was able to change some wrong but common concepts in the plastic recycling industry market.

For example, is it possible to hit 300 kilos per hour with the HIPS – GPPS granule line? Is it not possible? Is it not practical?

And we proved that yes, we can. When we act intelligently and scientifically; when the main focus is on ourselves and our customers; when we use new technology, when we realized that washing, separation and homogenization are important in granulation; we are able to produce 300 and even 400 kilos of HIPS – GPPS Compound per hour.

We boldly claim that we have introduced a new approach in the granulation industry of HIPS Crystals in Iran and we are still the leader in this field.

Episode Three

What is Exir’s next ambition?

Exir’s next ambition also happened. Since we saw the role of separation and washing in the quality of produced granules, we decided to purchase and install the largest, most modern and well-equipped acid washing line in Iran.

Accompanying and high-flying managers of Exir with the help of professional staff; Workers; foremen; engineers and valuable human resources in their service also implemented this plan.

Exir Polymer maintained and developed its position as a professional producer with excellent quality plastic recycling. In 2018, we purchased, installed and launched the largest modern acid washing line in Iran which cost about 4 to 5 times the cost of setting up a granulation line, in Ramsheh industrial town, and the production conditions changed from here on. During these days, we also purchased and installed two very large compactors and were able to complete the homogenization and mixing of polymers along with professional washing.

We had gained a strong and excellent position in the compounds and granules of HIPS- GPPS Compound and Polystyrene. We entered the big world of polypropylene (PP) with the same views and ideologies. We bought waste of cheese and yogurt’s packaging containers and washed them in our factory in Ramsheh. We continue the production of our traditional black crystal HIPS factory in Ramsheh with the same two normal lines.

On this date, in the production of strong and professional PP and PS granules and compounds, we have had a strong presence and an acceptable position in the Iranian market. With the same attitude and perspective, we launched the ABS production line and now we have been able to get a good share in the ABS market.

Yes, the quality of Exir polymer granules and compounds has been upgraded, because, with our modern professional washing line in Ramsheh, we improve the quality of the input materials, and by using large compounders and a large two-stage granule lines, professional mixing and homogenization is done completely.

These are part of Exir Polymer’s strategies to achieve and maintain excellent quality and ultimately customer satisfaction.

The Company’s Mission

Our duty is to support and satisfy our customers by producing polymer compounds with expected and uniform quality standards.

The uniformity of the quality of the manufactured product and not harming the environment in the production process and the final product can be seen in Polymer Elixir.

Our Product

Polypropylene Compound

Polystyrene Compound

Polyethylene Compound

Compound ABS

Polypropylene Compound

Certificates and licenses

We have 5 certificates: quality management (ISO 9001) – occupational health and safety management (ISO 45001) – environmental management (ISO 14001) – brand authenticity valuation (ISO 10668) – integrated management system certificate (IMS)

Authority for issuing certificates: EIQM Iran – Canada

فارسی

فارسی العربية

العربية